1. Introduction

When designing a switch-mode converter, electromagnetic

compliance is often tested in the later stages of the design phase. If EMI was

not considered during the initial stage of the design, it can often be difficult

or expensive to reduce EMI afterwards. The best way to ensure a smooth and optimal

product design is to consider EMI in the beginning phase of the design. Component

choice and layout considerations are crucial in obtaining good EMI performance

from the start.

2. Sources of EMI in Buck converters

EMI radiation can be generated by two sources: Alternating

electric field source (high impedance) or alternating magnetic field source

(low impedance). Non-isolated DC/DC converters have relatively low impedance

nodes and loops (much lower than the far-field impedance of 377Ω), so

magnetic fields are generally the main radiation source in DC/DC buck converters.

Magnetic field radiation is caused by a high frequency

current flowing in a small current loop. The current loop will emit high frequency

magnetic field, which gradually transitions into electromagnetic field when

the distance to the source exceeds 0.16λ (far field). The field strength

of a small current loop is approximately :

where f is the signal frequency in Hz, A is the loop

area in m2, I is the current amplitude in the loop in Ampere, and

R distance to the loop in meters.

As example, a 1cm2 current loop with 1mA

current with 100MHz frequency at 3m distance generates a field strength of 4.4µV/m

or 12.9dBµV.

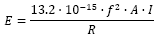

Figure 1 below shows the approximate radiation of a

1cm2 current loop with 1mA current at 3m distance as a function of

the frequency of the current. The green line shows the approximate EN55013 radiation

limit for 3m distance.

Figure 1

From the figure, it can be seen that radiation of a

1cm2 loop with 1mA rms high frequency current will not easily exceed

limits. The problem that often leads to exceeding the limits is when smaller

loops excite bigger loops or wiring attached to the PCB starts radiating. These

bigger loops or wires are much more effective antennas and will therefore have

much higher contribution to total radiation.

3. Identifying current loops in a Buck converter

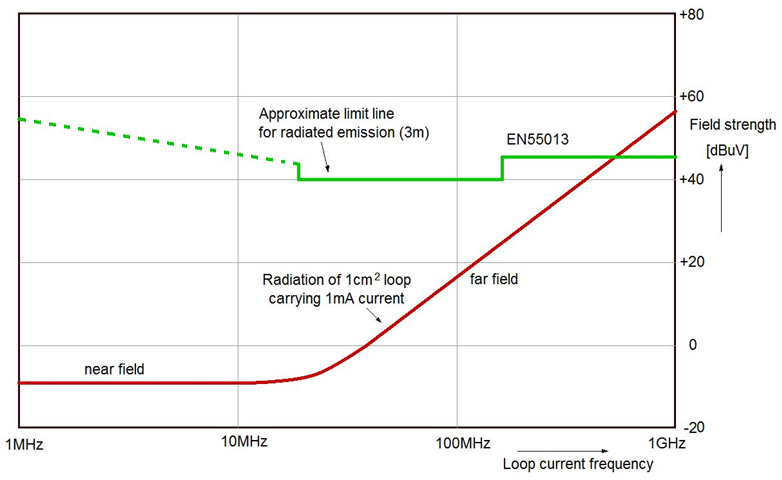

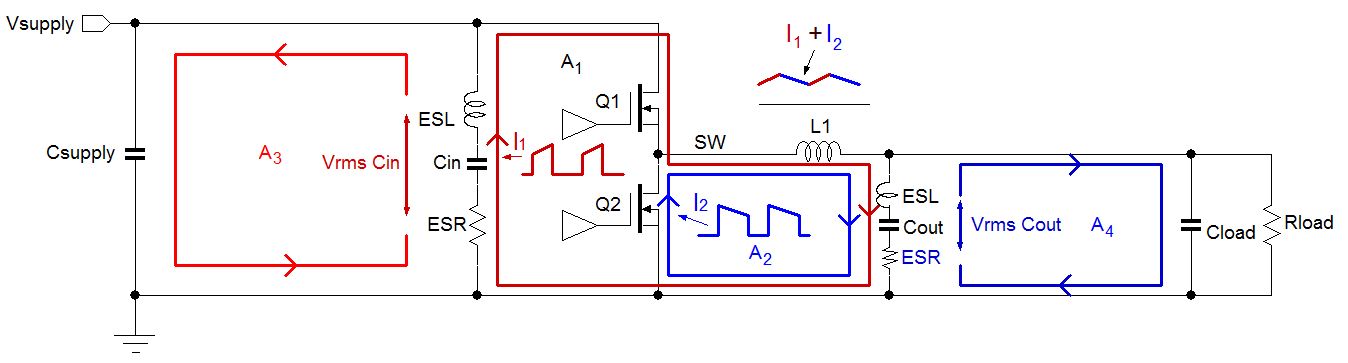

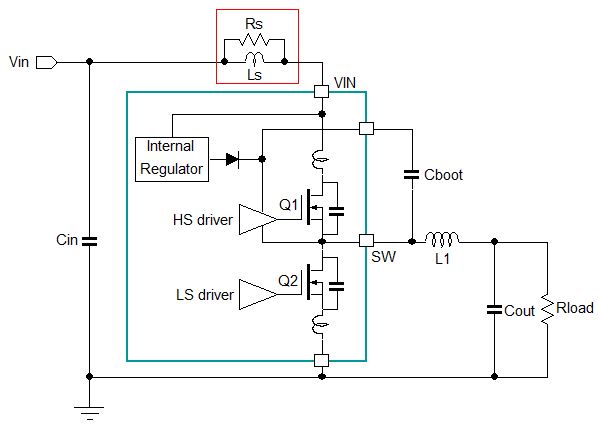

The DC/DC buck converter has two main loops where high

AC currents flow as shown in figure 2.

When the high-side MOSFET Q1 is on, the current flows

from supply via Q1 and L1 to the output capacitor and the load. The current

flows back via ground to the input. The AC portion of the current will flow

via the input and output capacitors. This current is shown in red color as I1

in figure 2.

When Q1 switches off, the inductor current will keep

flowing in the same direction, and the synchronous rectifier MOSFET Q2 is switched

on. The current flows via Q2, L1, load and output capacitor and back via ground

to Q2. This loop is shown in blue as I2. Both I1 and I2

are discontinuous currents, meaning that they have sharp rising and falling

edges at the beginning and end of the active time. These sharp edges have fast

rise and fall times (high dI/dt). Therefore they have a lot of high frequency

content.

Figure 2 : Buck converter current loops

I1 and I2 share a common path

from switch node to inductor to output capacitor to ground back to the source

of Q2. The sum of I1 and I2 is a relatively smooth continuous

saw-tooth waveform, which has less high frequency content due to the absence

of high dI/dt edges.

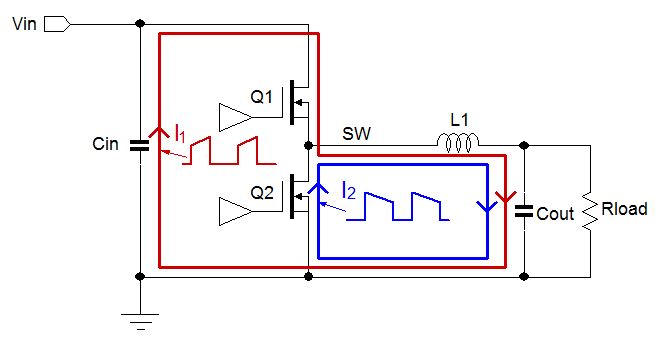

From EMI radiation point of view, the current loop with

the high dI/dt current is the shaded area A1 as shown in figure 3.

This loop will generate the most high frequencies and should be considered the

most critical loop for EMI in buck converters. The dI/dt of the current in area

A2 is not nearly as high as in A1 and generally generates

a lot less noise.

Figure 3

When setting up the PCB layout of a buck converter,

shaded area A1 should be made as small as possible.

See

chapter 7 for practical tips on layout.

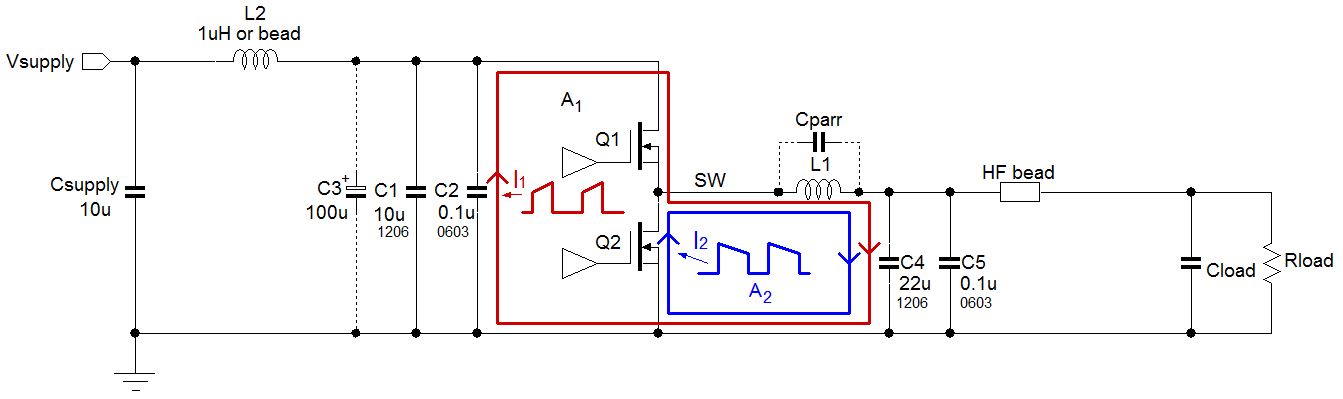

4. Input and output filtering

In ideal case, the input and output capacitors would

be very low impedance for the buck converter switching currents. But in practice,

capacitors will have ESR and ESL, which increases the capacitor impedance and

results in extra high frequency voltage drop across the capacitor. This voltage

will induce currents in the supply input line and connections to the load, as

shown in figure 4.

Figure 4

Due to the discontinuous nature of the buck converter

input current and the fact that the supply lines to the converter are often

quite long, the input loop A3 can radiate considerably or result

in exceeding conducted emission levels in the conducted EMC measurements (150kHz

~ 30MHz band)

To reduce the voltage drop across Cin, use low ESR MLCC

types and multiple capacitors of different size like 2x10µF 1206 and one

22n~100nF 0402 or 0603 size type close to the buck IC. To reduce the noise in

the input loop, it is highly recommended to add extra L-C filtering in the input

line. When using pure inductance for L2, it may be necessary to add the electrolytic

capacitor C3 to damp any input supply ringing and ensure stable input supply.

To filter the output, also use multiple different size

MLCC for Cout. Small 0603 or 0402 size 22nF~100nF capacitors can better block

high frequency noise that may be coupled from switch node onto the output via

the parasitic capacitance of the inductor L1. An additional HF bead will avoid

the output loop from becoming an effective loop antenna. It should be noted

that HF beads in the output can deteriorate the load transient response and

load regulation. If the application load is critical in this respect, don’t

use beads but place the converter as close as possible to the load, and minimize

the loop area by using copper planes in the output.

Figure 5 : Buck converter input and output filtering

5. Reducing buck converter switching speed

If the radiation levels of the buck converter circuit

still exceed requirement levels and layout or filtering cannot be improved,

then reduction of the buck converter switching speed can help reducing the radiation

levels. To understand the radiation reduction that can be achieved, let’s

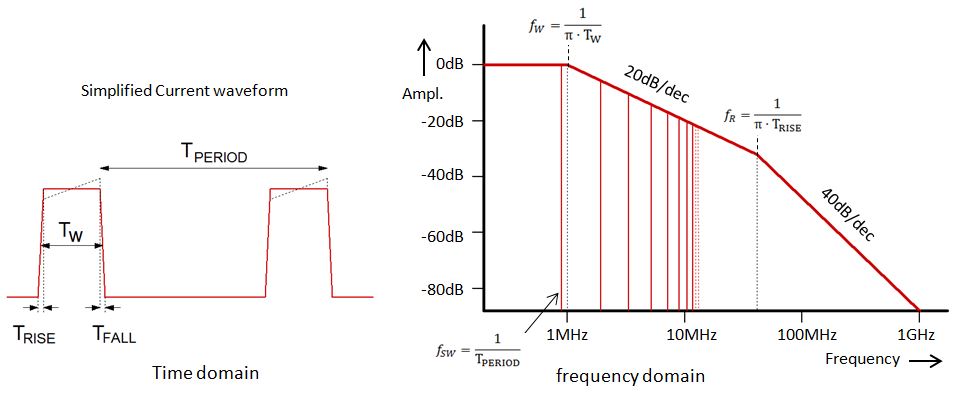

examine the frequency content of a discontinuous current pulse waveform.

Figure 6 left side shows the simplified current waveform

as a trapezoidal wave with period TPERIOD, width TW and

rise and fall times TRISE. The frequency domain will consist of the

fundamental frequency and many upper harmonics. The relation between the pulse

width, rise/fall times and amplitude of the upper harmonics can be derived via

Fourier analysis and is shown in figure 6 right side.

Figure 6 : Harmonic content of a pulse waveform

The figure 6 frequency values are based on an example

with 800kHz switching signal with a pulse width of 320nsec and 10nsec rise and

fall times. Radiated EMI problems often occur in the 50MHz~300MHz range, and

it can be seen that increasing rise and fall times will shift the fR

point to lower frequency, and the high frequencies will roll-off more quickly

with 40dB/dec. In the lower frequency range, the impact of slower rise and fall

times is quite limited.

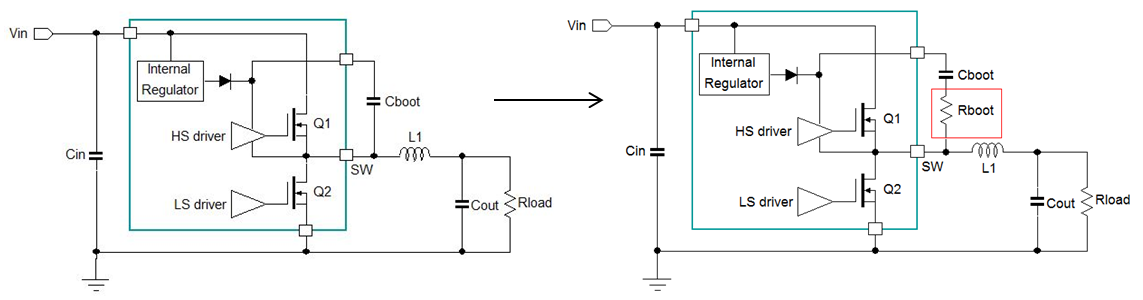

Adding series resistor in bootstrap circuit.

The switching waveform rise time is determined by the

switch-on speed of the high-side MOSFET Q1. Q1 is driven by a floating driver

that is supplied via a bootstrap capacitor Cboot. In integrated buck ICs, C

boot is charged via an internal regulator (normally 4~5V). See figure 7 left

side.

Figure 7 : Adding series resistor in bootstrap circuit

Increasing the rise time of the buck converter switch

waveform and current pulse can be accomplished by slowing down switch-on speed

of the high side MOSFET, which can be accomplished by adding a resistor Rboot

in series with Cboot as shown in figure 7 right side. The value of Rboot depends

on the size of the high side MOSFET. For most applications around 5~10Ω

is used. For smaller (higher Rdson) MOSFETs, larger Rboot values are allowed.

Too high values for Rboot may cause insufficient Cboot charging in high duty-cycle

applications, or cause instabilities in the IC current sense. Slower MOSFET

switch-on will also increase switch losses and reduce efficiency.

In designs were the MOSFETs are external, it is possible

to add a series resistor in high-side MOSFET gate. This will increase the high-side

MOSFET switch-on time and switch-off time.

When the high-side MOSFET Q1 is switched off, the inductor

current will charge the parasitic output capacitance of Q1 and discharge the

parasitic output capacitance of Q2 until the switch waveform goes below ground

and activates the body diode of Q2. The falling time is therefore basically

determined by the inductor peak current and the total parasitic capacitance

at the switch node.

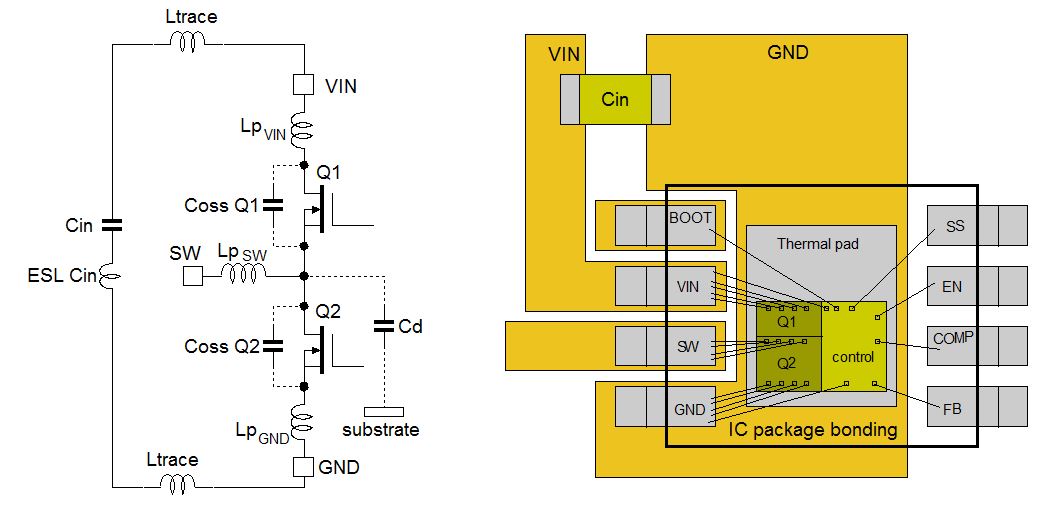

Figure 8 shows an example of the parasitic components

of a buck converter IC in a typical layout.

Figure 8

The parasitic capacitances are caused by the MOSFETs

Coss and capacitance to substrate. The bonding wires from IC pins to silicon

die will have some parasitic inductance. These parasitic components in combination

with the PCB layout parasitic inductance and input filter capacitance ESL will

cause high frequency ringing in the switching waveforms. When the MOSFET Q1

switches on, the ringing frequency in the positive edge is mostly determined

by Coss Q2 and the total parasitic inductance in the MOSFET switching loop (LpVIN

+ LpGND + LpLAYOUT + ESLCIN).

When the MOSFET Q1 switches off, the ringing frequency

in the falling edge is mostly determined by Coss Q1 and the parasitic inductance

in the low-side MOSFET source to ground (LpGND).

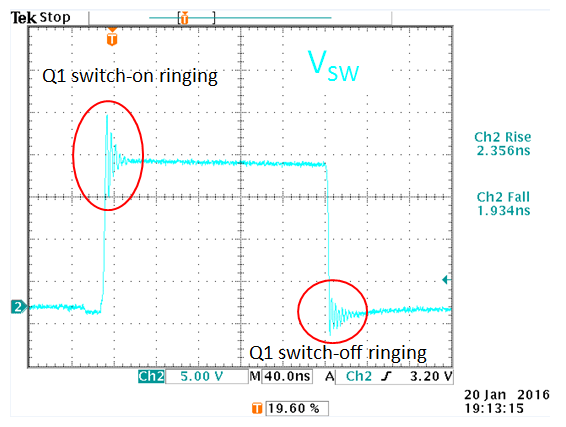

Figure 9

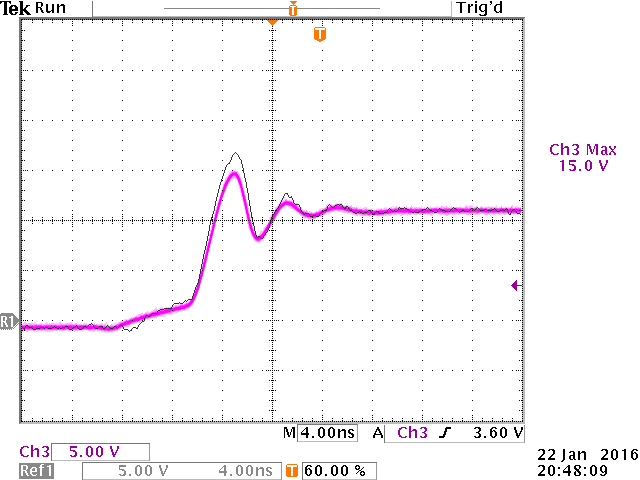

Figure 9 shows an example of a switching waveform with

fast rise and fall times and positive edge and negative edge ringing. Due to

the energy ½∙I2∙Lp stored in the parasitic inductance, the

ringing amplitude will increase with load current. The frequency range will

often be around 200~400MHz and results in high frequency EMI radiation. Excessive

ringing often points to larger circuit parasitic inductance, and the layout

should be checked for bigger loops or thin traces in Vin or ground. Component

package can also influence ringing: bonding wire packages will perform worse

than flip-chip packages due to the higher inductance of bonding wires compared

to pillar bonds.

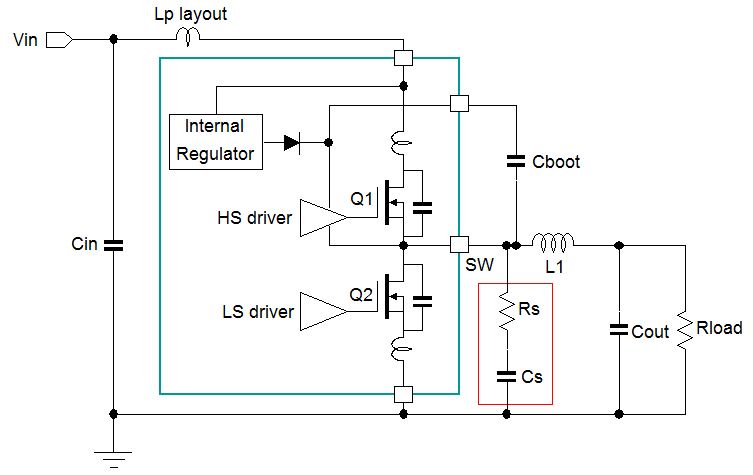

RC snubber damping

Adding an RC snubber can effectively damp out ringing,

at the expense of increased switching losses.

The RC snubber should be placed as close as possible

to the switch node and power ground. In buck converters with external MOSFETs,

the RC snubber should be placed directly across the drain and source of the

low side MOSFET. Figure 10 shows the placement of the RC snubber.

Figure 10

The aim of the snubber resistor Rs is to add sufficient

damping to the parasitic resonant LC circuit. The value for Rs depends on the

desired damping and the parasitic L & C components of the circuit and is

given by :

where ξ is the damping factor. Normally ξ can

range from 0.5 (slightly underdamped) to 1 (critically damped).

The values for parasitic Lp and Cp are normally not

known, and can best be measured in the following way :

1. Measure the original ringing frequency fRING

in the rising edge.

2. Add some small capacitance from switch node to ground,

and watch the ringing frequency become lower. Keep adding capacitance until

the ringing frequency is 50% of the original ringing frequency.

3. A 50% reduction in ringing frequency means that the

total resonance capacitance is four times the original capacitance. The original

capacitance Cp is therefore 1/3 of the added capacitance.

4. The parasitic inductance Lp can now be calculated

by

The series capacitor Cs of the RC snubber needs to be

large enough that the damping resistor can perform steady resonance damping

during the circuit ringing. Too large values for the capacitor will increase

power loss due to the charging and discharging of the capacitor each switch

cycle. Normally Cs is chosen 3~4 times larger than the circuit parasitic capacitance.

Besides resonance damping, the RC snubber will also

slightly increase rise and fall times of the switching waveform. However, the

charging and discharging of the snubber capacitance will result in extra switching

peak current spikes during switching transitions, which may increase EMI in

lower frequency areas.

After placing the RC snubber, be sure to check the total

power loss of the circuit : The converter efficiency will drop, especially at

high switching frequency and high input voltages.

RL snubber damping

A less obvious way to damp ringing in the switching

circuit is the addition of an RL snubber in series with the resonant circuit.

The buck converter with RL snubber is shown in figure 11. The aim is to add

a small amount of series resistance in the resonant circuit, sufficient to provide

some damping. Due to the fact that the total resistance of the switching circuit

is normally quite low, this damping resistor Rs can be low as well, in the order

of 1Ω or less. The inductor Ls is chosen to provide low impedance at lower

frequencies than the resonance, basically to short-circuit the damping resistor

in the low frequency range. Since the ringing frequency is normally quite high,

the required inductor can be small as well, in the order of a few nH, which

can be achieved via a few mm of thin PCB trace, so it does not significantly

increase the loop area. It is also possible to use a very small bead in parallel

with Rs as substitution for Ls; in that case the bead must have low impedance

at frequencies well below the resonance frequency, and must have sufficient

current rating for the input RMS current.

Figure 11

The RL snubber can best be placed close to the power

stage input node. One drawback of the RL snubber is that it creates impedance

Rs in the switching loop the high frequency region. During the very fast switch

transitions, the switch current pulse will create a short voltage glitch across

Rs, resulting in a small voltage glitch on the power stage input node. If this

VIN voltage glitch reaches too high or too low values, the power stage switching

or IC operation may be affected. Be sure to check the voltage glitch on VIN

node during maximum load switching when the RL snubber is added.

6. Practical example

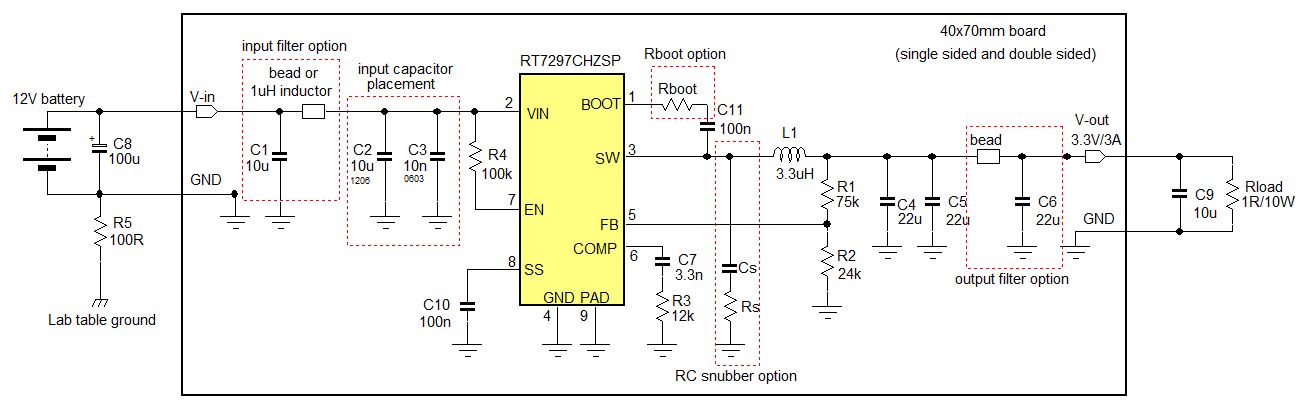

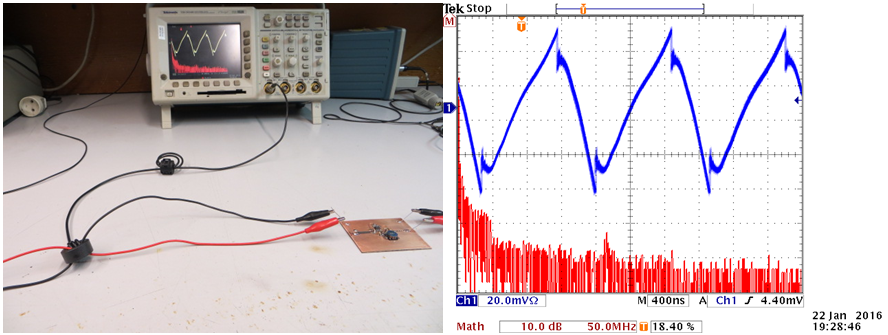

In this chapter shows the effects of several aspects

of buck converter design on EMI. We use RT7297CHZSP, a flexible 800kHz, 3A current

mode buck converter in PSOP-8 package which is tested in a 12V – 3.3V/3A

application. The schematic of the test setup is shown in figure 12.

Figure 12

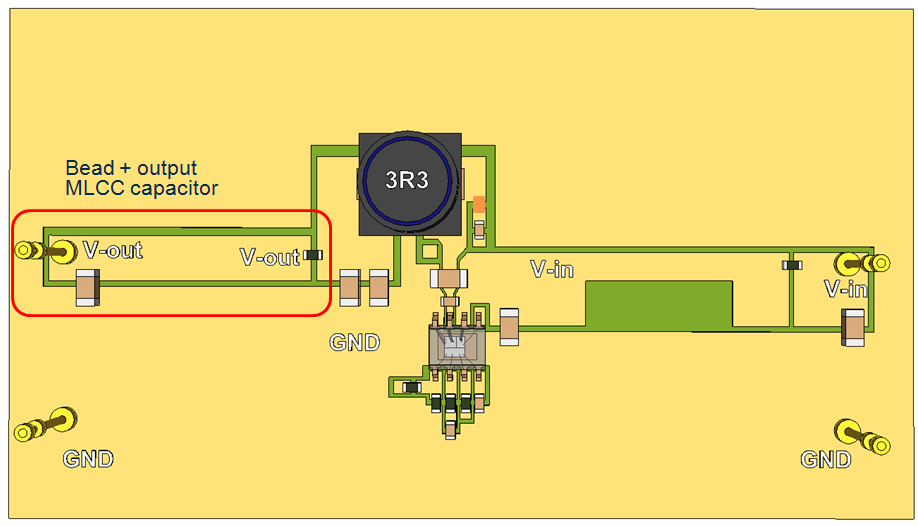

The test board was made in two versions : one with full

copper ground plane and one without ground plane.

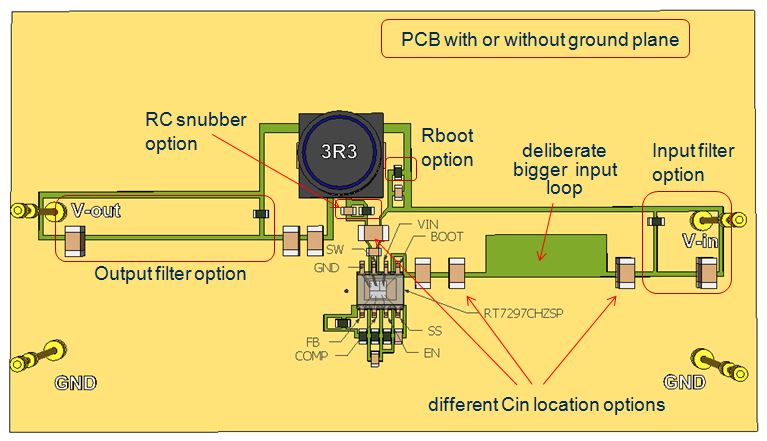

The board has several options like LC input filter,

different input capacitor placement, Rboot and RC snubber option and output

LC filter option. The test layout with the different options is shown in figure

13.

Figure 13 : EMI test board

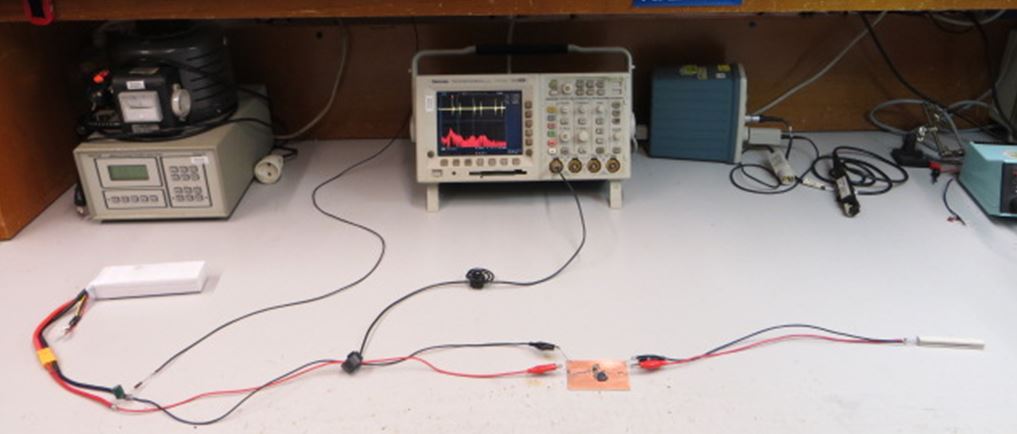

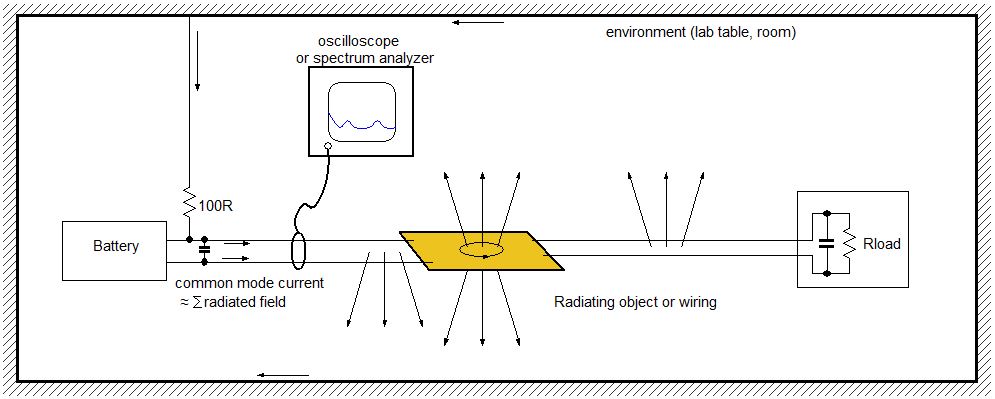

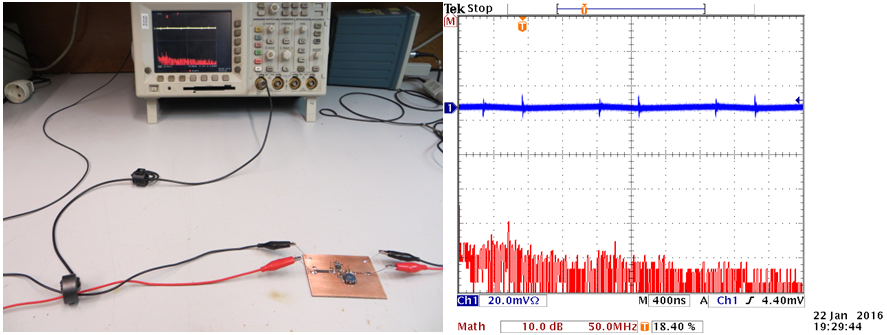

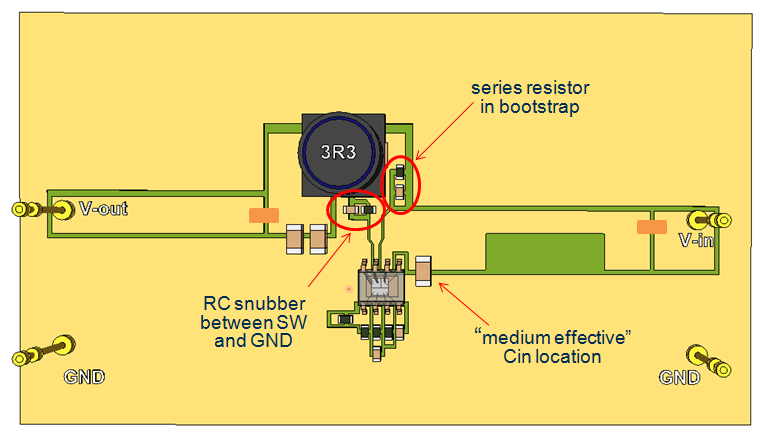

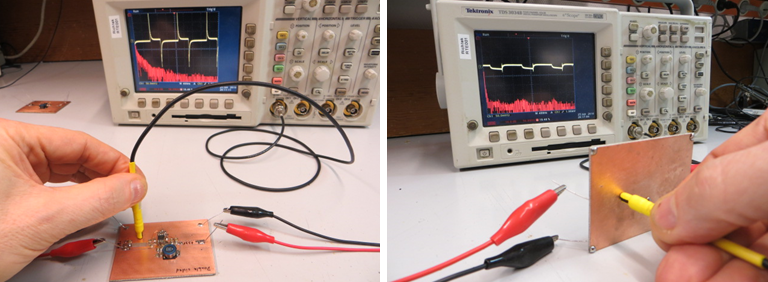

The test measurement setup is shown in figure 14.

Figure 14

When the board under test is placed on the lab table,

the PCB current loops and wiring will radiate HF energy to the environment.

This radiation finds its way back to the board as high

frequency common mode current in the supply leads. See figure 15. The high frequency

common mode current in the supply leads is basically the combined radiated field

current from the board, and can be used as an indication of radiated emission

when doing experiments.

Figure 15 : Common mode current caused by field radiation

The input supply for the converter is provided by a

3S (~12V) Li-Ion battery, to be independent of other lab equipment. There is

an electrolytic capacitor across the battery leads to eliminate resonances due

to battery inductance.

The converter load is a 1Ω resistor in parallel

with a 10µF MLCC capacitor. This provides a 3A load to the converter with

low impedance for high frequencies.

The ground lead of the input line at the battery end

is connected via 100Ω to the lab bench ground. This gives the circuit a ground

reference, with impedance similar as the EMC measurement LISN network.

The self-made EMI current measuring tool (see

chapter 8) can be placed in the supply input and output wires. In this report,

we use an oscilloscope to view the measured HF current signal, which will show

high frequency glitches during the converter switching transitions. For these

repetitive switch signals, it is possible to let the oscilloscope calculate

the FFT of the noise signal, to see the frequency content of the measured current.

Although this is nowhere as accurate as a spectrum analyzer, it is still quite

useful for experiments and judgment on a simple circuit.

Input capacitor placement

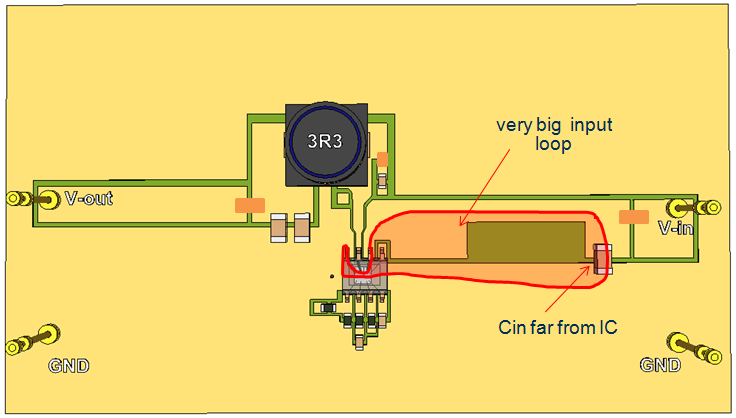

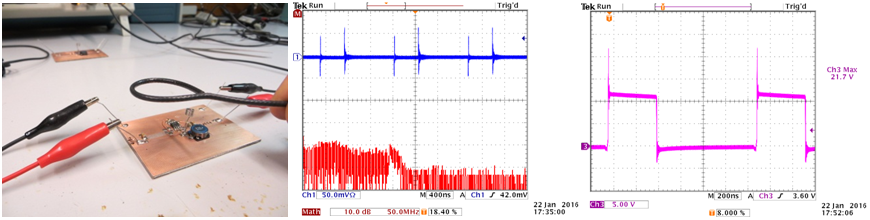

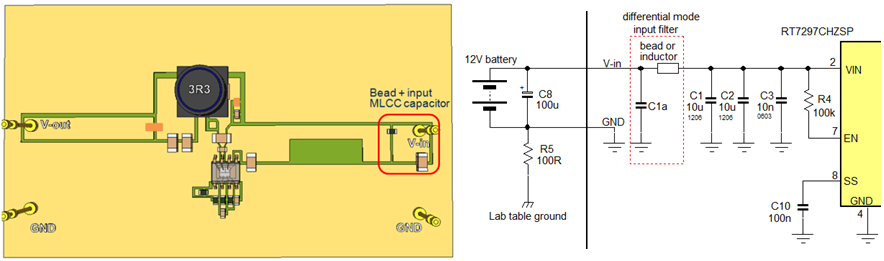

Experiment 1 : Place Cin far from the IC

The layout in figure 16 shows a bad placement of the

input capacitor, resulting in a switching loop with lots of parasitic inductance.

(The layout has some extra gap to increase the loop area)

Figure 16

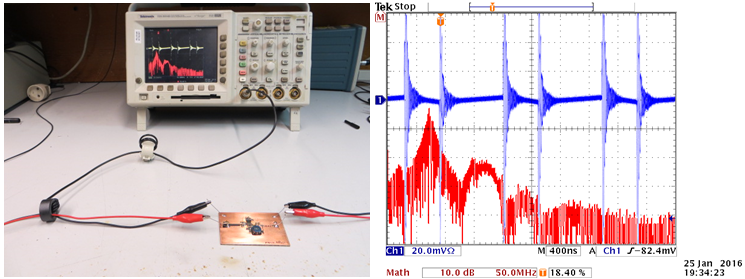

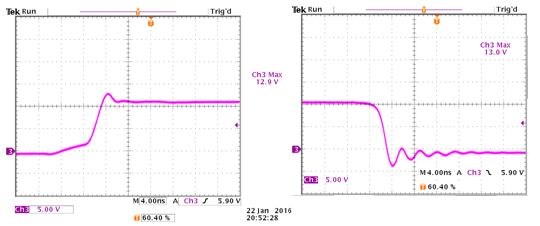

We first do a general check on radiated noise by measuring

the common mode current in the input wires

Figure 17 : Common mode current measurement in input wires

Figure 17 right side shows that the common mode current

is extremely high and extends over a wide frequency band.

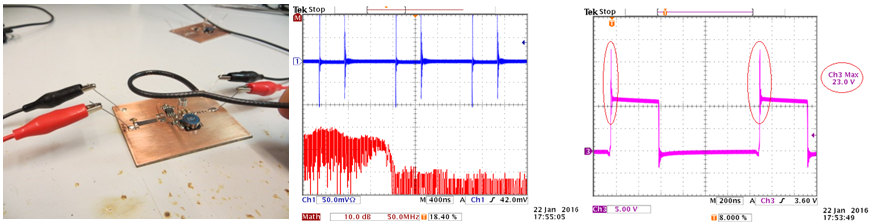

We can examine the source of the common mode current

by using the loop antenna to search for radiated fields on the PCB. When the

loop antenna tool is held above the input loop, the scope shows a lot of radiated

noise in low and mid frequency range up to 200MHz above the Cin loop, see figure

18.

We also see that the switching waveform has a very big

overshoot and ringing, actually exceeding IC voltage ratings. So the bad placement

of the input capacitor gives both high radiation and big waveform ringing.

Figure 18 : Measuring radiated field from big CIN

loop on single sided PCB

If we do the same measurement on the board with a ground

plane on bottom side, it can be seen that the radiation from the big Cin loop

with the ground plane is much lower than with the single sided board. Switching

ringing is also slightly lower in the board with the ground plane, see figure

19.

Figure 19 : Big CIN loop on double sided PCB

with ground plane

The HF magnetic field from the big loop creates eddy

currents in the bottom ground plane which create a field in opposite direction

that partly cancels the original magnetic field. The closer the ground plane

to the loop, the more effective it will be.

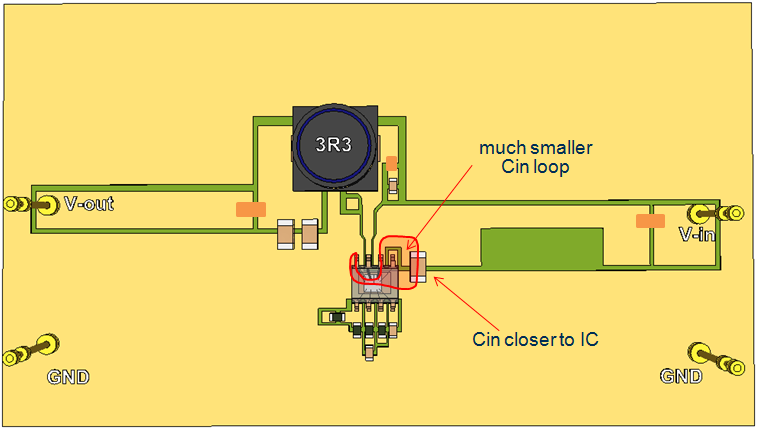

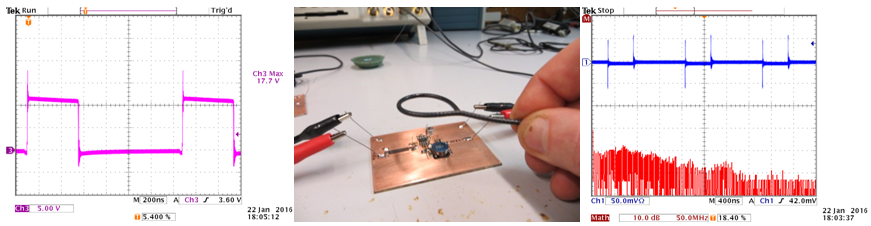

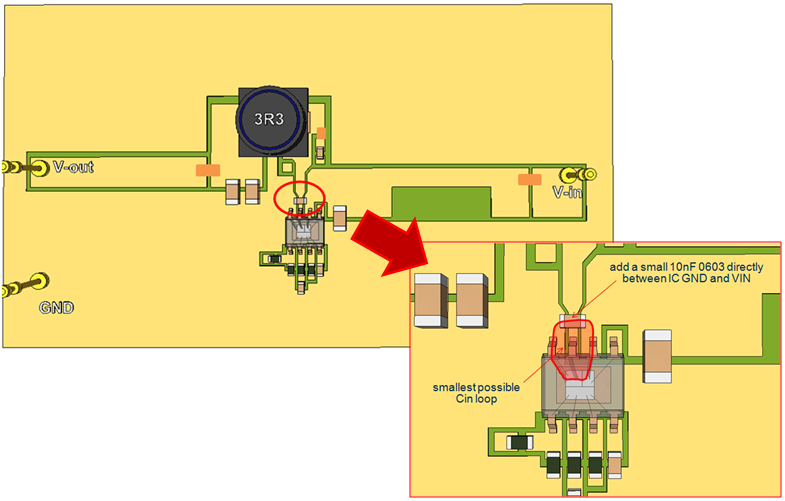

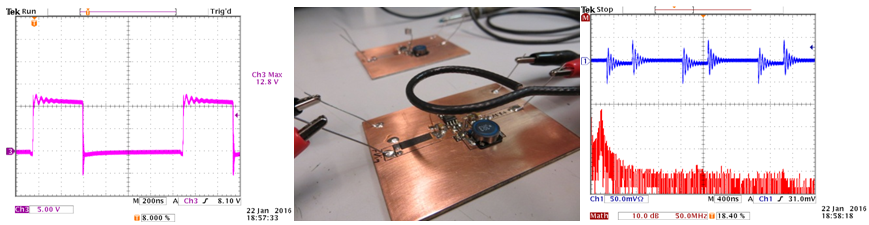

Experiment 2 : Cin closer to the IC.

We continue with the single sided PCB, and place the

Cin capacitor close to the IC, which results in a much smaller Cin loop. See

figure 20.

Figure 20 : Better placement of CIN

The switching overshoot and ringing is around 50% lower,

and radiated emission has dropped around 10dB.

The frequency band extends now to 300MHz range.

Figure 21

It is important to realize that the better placement of

Cin will improve both switching waveform overshoot & ringing and reduce

the HF radiation.

|

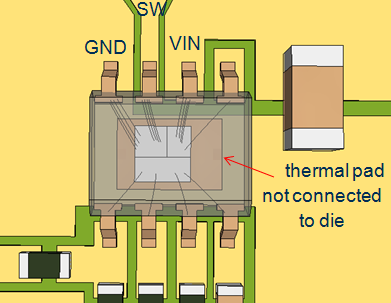

In RT7297CHZSP, the thermal pad is not connected

to the die, so the layout copper connection to the thermal pad does

not shorten the Cin loop. The high side and low side MOSFETs are

connected via multiple bonding wires to the VIN and GND pin. So

the shortest loop is via these two pins.

|

|

Experiment 3 : Add an additional small 10nF capacitor

directly between the IC VIN and GND pins.

Figure 22 shows the placement : The Cin loop is

now basically determined by the IC pins, bonding wires and 0603 capacitor

size.

Figure 22

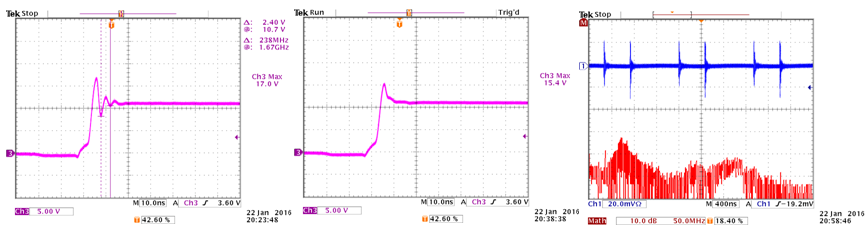

The switching waveform overshoot is virtually gone,

but a lower frequency ringing has appeared.

The measurement loop has to be positioned closer

to the PCB : The high frequency noise is gone, but there is a large peak

in the low frequency area around 25MHz.

Figure 23 : Adding single 10nF 0603 between ic GND

and VIN pins

The low frequency resonance is a result of two capacitors

in parallel in different loops with different resonances. This often happens

during EMI trouble shooting, and the loops and resonances should be identified.

In this case, the 10nF resonates with a 4nH parasitic inductance (~3mm conductor

length), creating a 25MHz resonance. The resonant loop is the small 0603

capacitor with IC pins, bonding wire and layout traces, which make a loop

with around 3mm length.

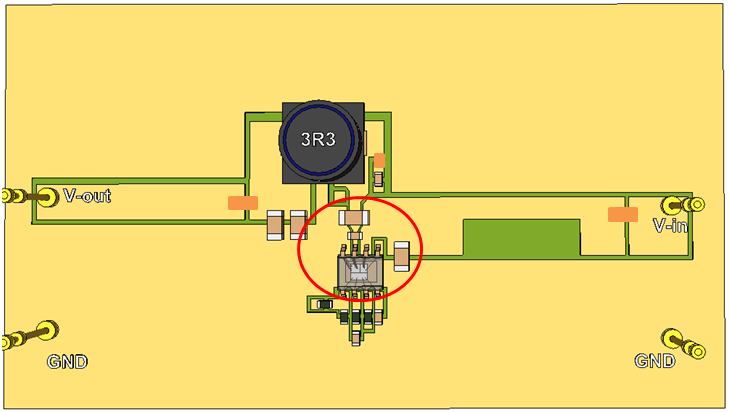

The solution can be found by adding a large 1206 22µF

capacitor with slightly higher ESR in parallel to the small 10nF capacitor.

The layout with optimal Cin capacitor locations is

shown in the layout of figure 24.

Figure 24

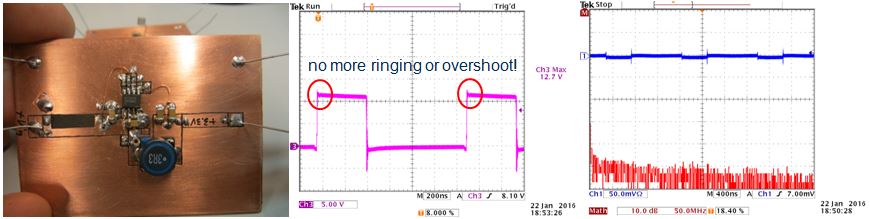

With above solution, the single sided board switch

waveform overshoot is virtually gone, and the radiated noise pick-up from

loop antenna is also very low; the FFT waveform is mainly at the noise floor

level.

Figure 25 : Final solution with shortest CIN

loop

If we now measure the common mode current in the

input wire with the HF current probe, we see that the common mode noise

has dropped a lot, more than 30dB at some frequencies when compared with

the first measurement. This means that the total board radiation level is

now quite low.

Figure 26 : Final solution common mode measurement

Input supply wire filtering

The high frequency current in the input supply wire

consists of both differential mode and common mode currents. Common mode

noise can be reduced by minimizing the area of the high dI/dt current loops

in the board layout. Input wire differential mode current has different

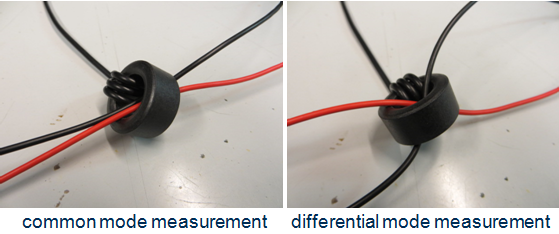

source. It can be measured with the self-made current probe by passing the

+ and – wires through the core in opposite direction as shown in figure

27 below :

Figure 27 : Differential mode current measurement

The differential current that we measure is caused

by the buck converter pulsing input current passing through the input capacitors,

causing a voltage drop across the capacitance and ESR of the input capacitor

and layout ESL if it is included in the loop. This voltage drop results

in a differential mode a current in the input supply wires.

It is possible to reduce this differential mode

current by increasing the input capacitance, but it is much more effective

to add a small LC filter in the input wire as shown in figure 28 right side.

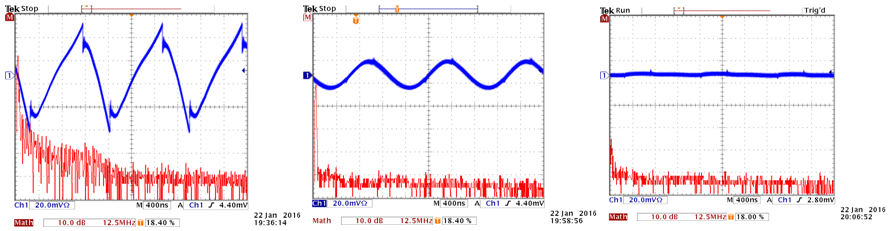

Figure 28 : Input filtering

| Without

extra input filter |

With

input filter 10µF 1206 MLCC + 0603 bead 2A BLM18PG121SN1

|

With

input filter 10µF 1206 MLCC + 1µH inductor LQH3NPN1R0

1.5A |

|

Figure 29

As can be seen from figure 29, adding a bead +

capacitor will remove all high frequency except the 800kHz fundamental;

Using a 1µH inductor + capacitor will remove all differential

mode noise including fundamental.

Output wire filtering

When measuring the differential mode in the output

supply, there is not much high frequency content, due to the continuous

output current without high dI/dt. There is however considerable lower

frequency noise up to around 30MHz. Most of the differential current

in the output leads is caused by the converter inductor ripple current

passing through the output capacitors, which also have some ESR. Adding

an extra LC filter by means of bead and MLCC capacitor as shown in figure

30 will remove most of the differential noise.

Figure 30 : Output filtering

|

Measuring differential mode current in the 3.3V output leads

|

Without extra output filter |

With output filter 22µF 1206 MLCC + 0603 bead 4A BLM18SG700TN1

|

|

Figure 31

Quite often, some inductor stray magnetic field

is coupled into the output loop as well.

Shielded inductor types have low stray fields

and will not easily couple into the output loop. But in case non-shielded

or semi-shielded inductors are used, the output loop area to the

load needs to be minimized to avoid stray magnetic field coupling.

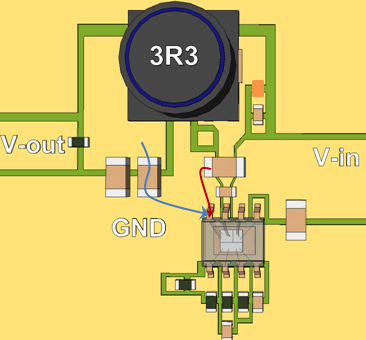

Reducing ringing by adding series resistance

in bootstrap circuit and RC snubber.

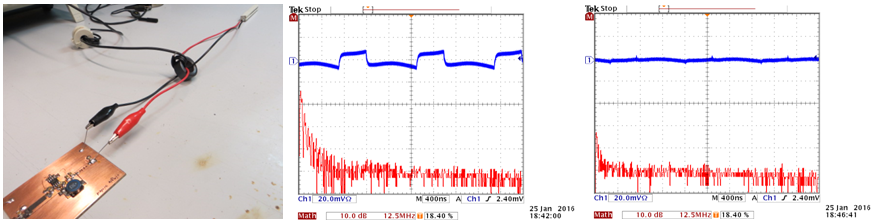

For this experiment, we use the double sided

board with input capacitor location as shown in experiment 2. This

setup gives significant radiation from the input loop.

Figure 32

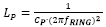

As reference measurement, the input supply

common mode current was measured without Rboot or RC snubber. The

switch waveform shows 5V overshoot with 238MHz ringing frequency.

Common mode current in the supply wires shows considerable high

frequency noise, see figure 33.

Figure 33 : Reference measurement switch waveform

and common mode current

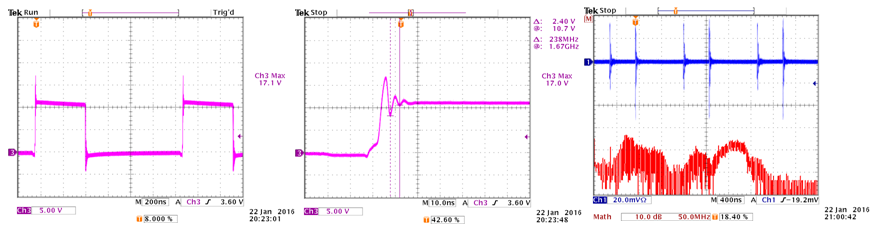

RT7297C has a relatively small high side

MOSFET (110mΩ), so the impact of adding low values of series

resistance to the bootstrap circuit is relatively small. It was

found that Rboot needed to more than 20Ω to see any change

in the switching waveform. Below scope picture shows the original

waveform with 0Ω (reference in grey) and the new waveform

when adding 33Ω series resistance, reducing the overshoot

to 3V. The impact of this change to the common mode current was

very small, hardly measureable in this simple measurement setup.

Figure 34 : Ringing before and after adding

33Ω Rboot

For determining the RC snubber values, we

use the method as described in

chapter 5 :

Original fRING = 238MHz. After

adding 220pF, fRING becomes 114MHz. CP is

thus 220pF/3 = 73pF.

LP can be found from

; LP = 6.1nH.

; LP = 6.1nH.

RS can be calculated from

; when we use ξ = 0.5 we get RS = 9.1Ω, we choose

8.2Ω

; when we use ξ = 0.5 we get RS = 9.1Ω, we choose

8.2Ω

CS is chosen 4xCP

and becomes 330pF.

|

Waveform before RC snubber |

Waveform after RC snubber |

Common mode with snubber |

|

Figure 35 : Effect of RC snubber on

switch waveform and common mode current

Adding the RC snubber will reduce the

common mode current in high frequency range around 5dB.

|

Rising edge is clean without ringing |

Falling edge has not changed much |

|

Figure 36 : Switching waveform with

both solutions : RC snubber 8.2Ω & 330p and 33Ω

Rboot

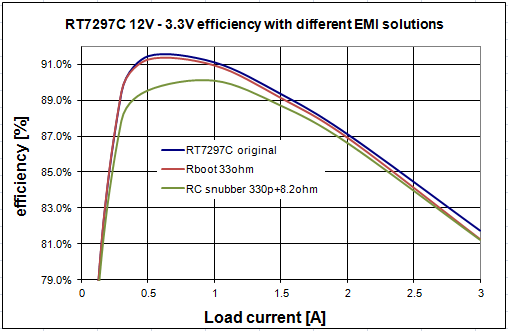

Figure 37 : The difference in efficiency

when snubber and Rboot are added

As can be seen, Rboot has little

effect on efficiency, except a small efficiency drop at

higher load.

The RC snubber has more impact on

efficiency, especially in the low and mid load range, but

still only 1~2% max, which is acceptable. It should be noted

that buck converters that operate at higher switching frequency

and higher input voltages will show higher losses when snubbers

are applied.

7. Buck converter layout tips

A good buck converter layout starts

with good planning where to place the key components.

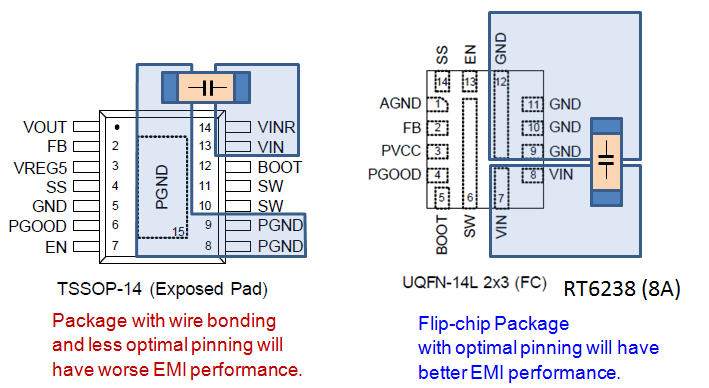

1. In noise sensitive applications,

choose buck converters in small, low inductance flip-chip

packages.

Figure 38 : Different packages will

give different input loop area and stray inductance.

2. Identify the VIN and GND node

of the switching loop, and place different size input capacitors

as close as possible between these nodes, the smallest size

capacitor closest to the nodes. This input switching loop

carries the very high dI/dt currents, and should be kept

as small as possible.

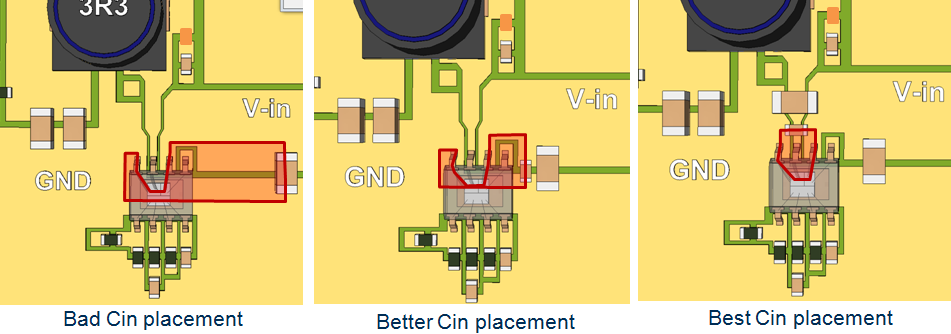

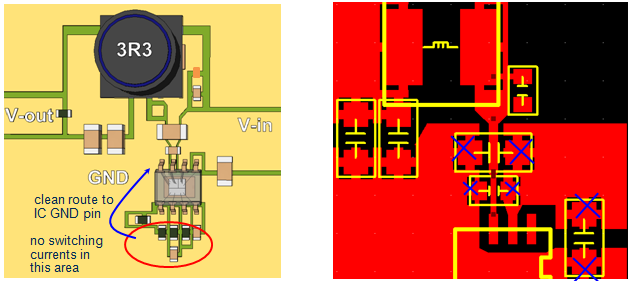

Figure 39 : Layout examples with different

input capacitor placement

3. Place the output capacitor ground

in an area that does not overlap the input capacitor switching

loop : this could generate extra high frequency noise in

the output voltage.

Figure 40

4. The traces from the switching

node and BOOT pin carry high dV/dt voltages, and can cause

some electric field radiation, so the trace copper area

should be kept relatively small, and away from other sensitive

signals.

5. The converter small signal section

should be away from the high power switching section. The

grounding of the small signal section should preferably

be a clean low noise ground point. Do not ground small signal

section in the area where the VIN decoupling currents or

output ripple currents flow, see figure 41 left side.

Figure 41

6. Do not use thermal relief in

component layout for critical loops, they create extra inductance

See figure 41 right side.

7. When using ground planes, try

to keep these planes as solid as possible below the input

switching loop. Any trace that cuts the ground plane in

this area will reduce the ground plane effectiveness. Signal

vias create holes in the ground plane, increasing impedance

as well.

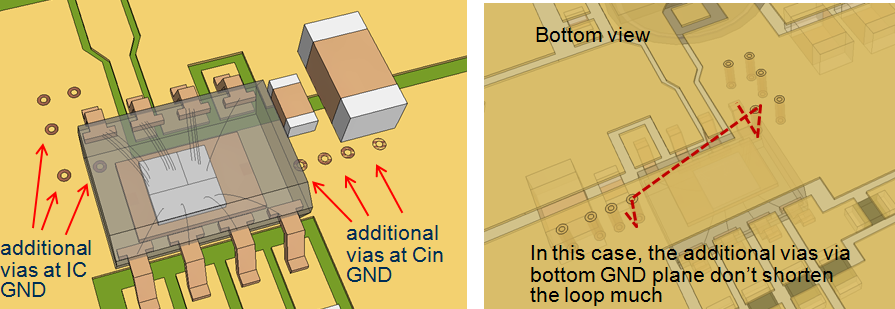

8. Vias can be used to connect decoupling

capacitors and IC ground to the ground plane, and loop can

be shortened. But keep in mind that via inductance can range

from 0.1~0.5nH (depending on via thickness and via length),

and may increase the total loop inductance. Multiple vias

should be used for lower impedance connection.

Figure 42

In above example, the additional

vias to bottom ground plane do not help a lot in reducing

the Cin loop. But in other cases where the top layer loop

is long, reducing loop area with vias to the ground plane

is quite effective.

9. Note that using the ground plane

as return for loop currents will make the ground plane noisy.

You can isolate by using a local ground planes, and connect

it to the main ground at a point with lowest noise.

10. Ground planes loop shielding

effectiveness increases when they are closer to the radiating

loop. In multi-layer PCBs, place the solid ground plane

on layer 2, directly below the top layer that carries the

high power currents.

11. Non shielded inductors generate

a lot of magnetic stray fields, which can radiate into other

loops or filter components. Semi-shielded or fully shielded

inductors should be used in noise sensitive applications

and sensitive signals and loops should be kept away from

the inductor.

8. Simple EMI probing tools you can

build yourself

Measuring EMI compliance often means

you have to bring the prototype product to an EMI facility

for testing. These are normally 3m sites in anechoic chambers,

with special measurement setups using antennas and expensive

measurement receivers. The measurement data shows the final

results of the complete setup, but it is not always easy

to find the root cause of specific radiation frequency emissions

from these 3m measurements.

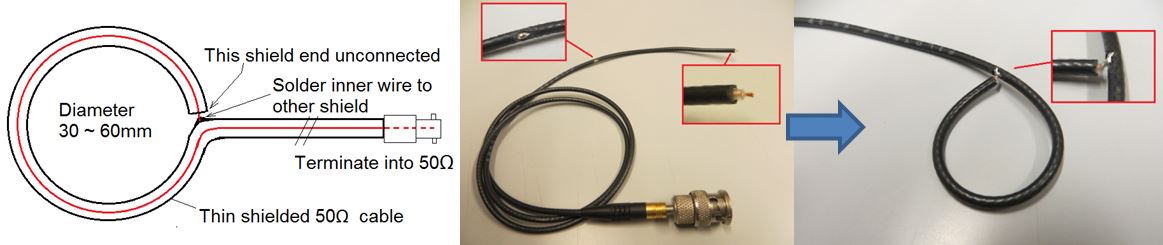

It is possible to do some basic

EMI measurements on a prototype product in the lab environment,

and examine system blocks separately. These measurements

are normally near-field (measuring distance < 0.16λ),

so for measuring radiation that originates from current

loops, you need a small loop antenna for measuring high

frequency magnetic fields. A small electrically shielded

loop antenna can be easily made yourself using a length

of thin 50Ω coaxial cable : see figure 43.

Figure 43 : Loop antenna construction

The loop antenna can be connected

to a spectrum analyzer and by moving the loop over the PCB

of your application, you can see which areas emit a lot

of high frequency magnetic field. You can also connect the

loop antenna to an oscilloscope (terminated in 50Ω)

and the oscilloscope will show switching noise levels in

certain areas of the PCB. By keeping the loop at a fixed

distance and place, and making some changes to circuits/PCB

loops, you can check whether radiated noise levels will

increase or reduce.

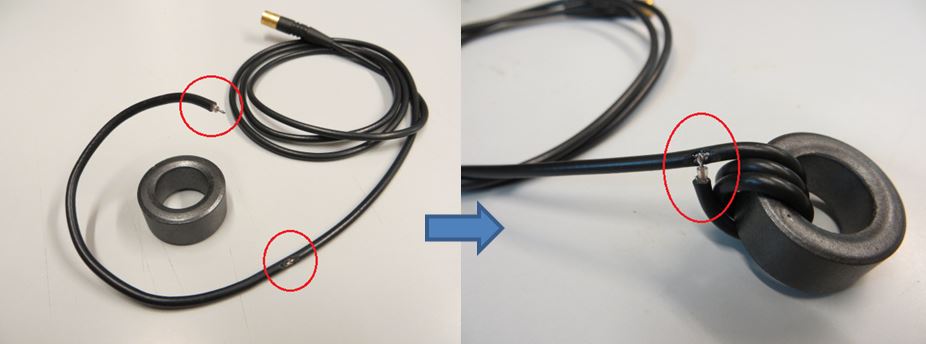

Since radiation from supply wires

can contribute considerably to EMI levels, you can also

measure the high frequency current in wiring. Not all current

probes have sufficient bandwidth to highlight EMI, but a

couple of windings on an EMI ferrite core will form a high

frequency current transformer. Construction is similar to

the loop tool, but now the loop has 3 turns around the ferrite

core. See figure 44.

Figure 44 : High frequency current

probe construction

The high frequency current in cables

can now be measured by passing a cable through the ferrite

core. The current transformer output can be connected to

spectrum analyzer or oscilloscope (terminated in 50Ω).

To avoid common mode current flowing

from the tested device to the measurement equipment, it

is recommended to add a common mode choke in the cable :

this can be done by placing a clip-on EMI core with a couple

of windings in the cable to the analyzer.

Figure 45

Passing both positive and negative

supply wire in the same direction though the core will measure

the common mode current in the supply wires. Reversing one

wire direction will measure differential mode current, see

figure 45.

Another handy tool is the current

sniffer probe. It is a miniature current transformer with

open core, see figure 46. It can be used to measure high

frequency currents in copper traces or component pins.

Figure 46 : Current sniffer probe

construction

It is a bit harder to build yourself.

You can grind the open core from a small two holed ferrite

bead and add around 4~5 windings, then connect the windings

to a coaxial cable. It is best to place the core in the

shield opening. When using this tool, you should be aware

that it can pick up some electric fields as well. To determine

whether the measurement result is magnetic field or electric

field pick-up, you can turn the tool 90 degrees on the trace.

Magnetic field measurement will almost reduce to zero, electric

field pick-up will hardly change.

Figure 47 : Current sniffer probe

use

The current sniffer probe will let

you check how various high frequency currents are flowing

through the board and component leads. It can even show

how the currents flow through copper planes : You’ll

find that a high frequency current in a copper plane will

choose the shortest route. Also the eddy currents in the

ground plane can be measured.

All measurements in this document

were made with the tools described here.

9. Conclusion

Solving EMI can be complex, especially

in complete systems without knowing the source of the radiation.

With some basic knowledge of critical high frequency signals

and loops in switching converters, component and layout

behavior at higher frequency and using some simple self-made

tools, it is possible to trouble shoot EMI, pin-point the

radiation sources and find low cost solutions to reduce

radiation.

The major radiation source in buck

converters is the converter input switching loop, and this

loop should be the first focus point. Switching converters

with different package construction can play a role in finding

the best component placement for lowest EMI radiation.

Reducing converter switching speed

can help reduce EMI, but this should not be the first action

to reduce EMI. Shielding by means of ground planes can be

effective, as long as the ground planes are solid and as

close as possible to the radiating loop. Filtering of input

and output supply leads can help to reduce conducted EMI

levels.

References :

Fundamentals of Electromagnetic Compatibility 2nd

edition, by B. Danker